This system is ideal for painting companies, ensuring not only compliance with VOC emission regulations, but also the possibility of recovering and reusing solvents, reducing operating costs and turning an environmental obligation into a new source of savings and profit, with a low investment.

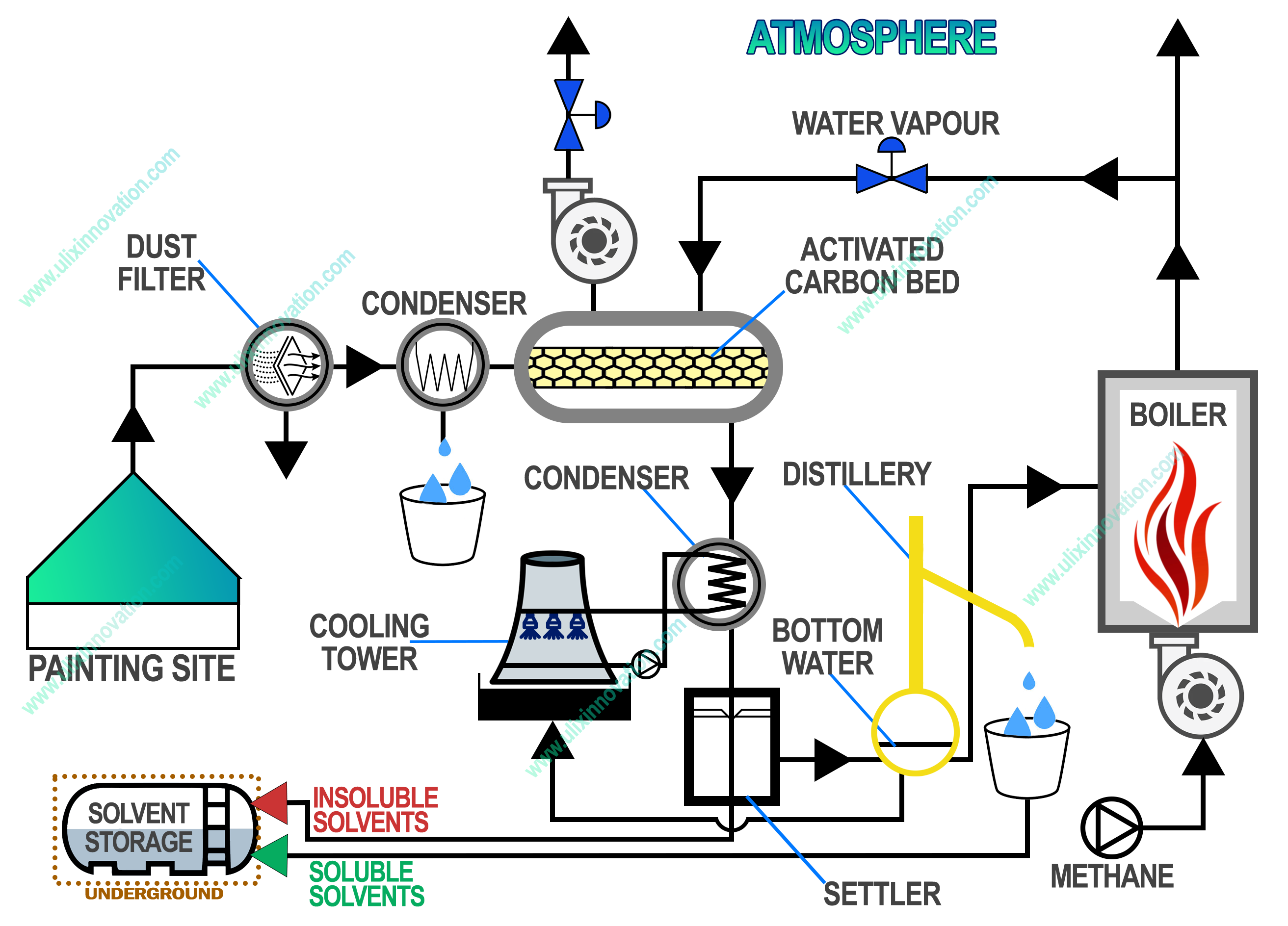

This process applies to painting lines, which, due to their nature, release volatile organic solvents (VOC) in gaseous form, consequently polluting the surrounding air. The advantage of the ULIX Innovation process is that it purifies the air by recovering solvents, ensuring emissions not only remain within legal limits, but also providing the customer with profit from a waste product.

The advantages are:

• Environmental: Solvents are recovered and reused to produce new paints, ensuring a virtuous cycle of circular economy.

• Economic: Economic incentives are available in many countries for ZERO EMISSION processes (white certificates).Additionally, the recovered solvents will be purchased from the customer, guaranteeing annual profits of up to €60,000.

The ULIX system captures all solvent-contaminated flows from various emission points in painting booths, making it a much more efficient investment compared to afterburners, both in the short term (competitive pricing) and in the medium-long term (methane consumption is an order of magnitude lower than afterburners).

The solution offered by ULIX allows for a ZERO EMISSIONS system in the atmosphere, both in terms of VOC and air flow.

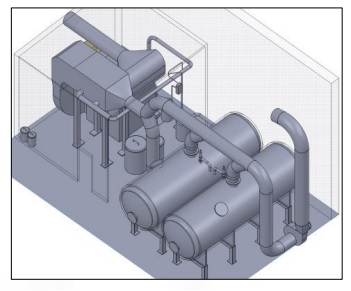

The system is delivered turnkey, complete with electrical panel, electrical system, PLC, and HMI, installed, calibrated, and ready for production. The sizes range from 5 x 15 m for air flows of 10,000 Nm³/h to 5 x 25 m for flows of 20,000 Nm³/h. We provide on-site maintenance services to ensure uninterrupted production activities.

ULIX also provides a collection and purchase service for the recovered solvent mixture.

ADVANTAGES OF ULIX INNOVATION TECHNOLOGY:

• High solvent reduction efficiency (up to 99%)

• FULLY GREEN system (ZERO EMISSIONS)

• Solvent recovery and resale + cost savings + no environmental impact in the production process

• Government economic incentives in many European and non-European countries

• Low energy consumption and reduced operating costs

• Modular system allowing for future expansions based on the air flow to be treated

TECHNICAL SPECIFICATIONS OF THE SYSTEM:

Air flow to be treated: 5,000 to 150,000 m³/h

Type of solvents to remove: Any (polar or non-polar)

Average water consumption: Approximately 1,500 m³/year for 10,000 Nm³/h of air to be treated

Nitrogen consumption: 0.3 m³/h for every 10,000 Nm³/h of air to be treated

Electricity consumption: ≈150 kW for every 10,000 Nm³/h of air to be treated

Waste disposal costs: None (only dust from the filter)

Services offered by ULIX INNOVATION:

• 2D and 3D plant design

• Space study and custom layout realization

• Testing, assembly, and preparation of the system in our workshop

• Issuance of all certificates and system calibration

• Transport and installation of the system at the client’s site

• Installation service to ensure the correct operation of the system

• Preventive maintenance for proper system use

• Technical solutions to minimize downtime

• Collection and purchase of recovered solvents at the client’s site