The process of producing biogas is divided in three phases: the production itself, the treatment and the upgrading.

Biogas is produced by a process of anaerobic digestions, where biomass is placed in a special plant in fixed conditions of pH and temperature where bacteria process the organic matter turning it into the biogas.

Unfortunately, the so obtained gas can’t be used as it is, but it requires some fundamental treatments to get a high quality product which can be used in the production of energy (cogeneration plants).

Biogas, in fact, needs to be purified from the compounds that can be damage the mechanical parts, especially hydrogen sulphide and ammonia, causing quick corrosion, wear and malfunctioning.

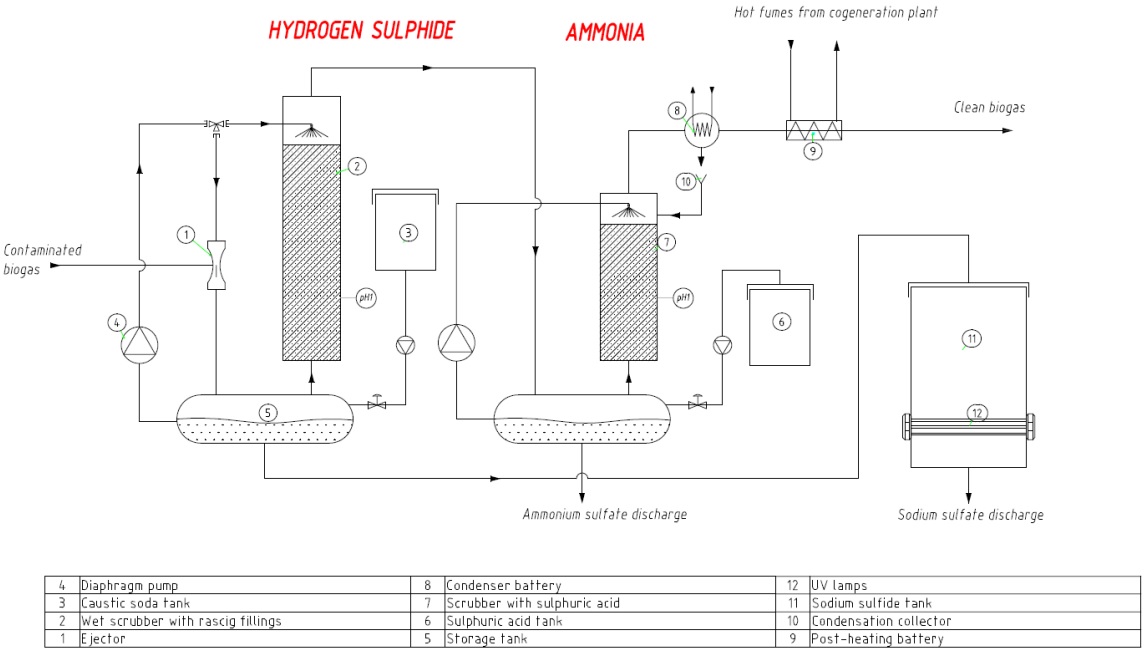

The following scheme shows the working principle of our plant for sulphur and ammonia abatement in detail.

In a typical configuration of a ULIX Innovation plant, contaminated biogas is sucked by an ejector or a blower (1), which removes from 90 to 95% of the hydrogen sulphide, and further washed with a scrubber (2) filled with a saturated caustic soda solution (3) in order to neutralise it completely.

It’s possible to use two reactor tanks to increase the efficiency of removal. Once it reaches a neutral pH, the solution is discharged and replaced with a fresh one. Sulphides produced from the reaction are stored in a tank (14), oxidized to sulphates with a UV lamp (9), and discharged to the aquifer as

inert compound. Similar procedure is carried out with the ammonia by mixing biogas with sulfuric acid (6).

The plant it completely automized and controlled by control panel.

ADVANTAGES OF ULIX “INNOVATION TECHNOLOGY”

– High efficiency of pollutants removal (<1ppm)

– ZERO costs of waste chemical disposal

– Low maintenance costs

– Compact plant moveable with a trailer

SERVICES OFFERED BY ULIX INNOVATION

– Design and optimization of the production process and vacuum lines

– Training sessions of personnel for the complete utilization of the plant

– Start-up and monitoring of the plant after installation

– Real-time remote assistance to check the right functioning of the plant