This plant is meant for companies which produce EPS and polyurethane foam which guarantee not only to comply with the emissions limits, but also to recover the solvent and resell it, with a low cost investment.

Pentane is a hydrocarbon which is largely used in the process of expansion of polystyrene. During this process, polystyrene spheres are impregnated with pentane and expanded by a water vapour stream in which the dimension of the spheres grows up to 20 times. One third of the pentane used in the process stays inside the spheres but the remaining two thirds is let out in the atmosphere causing sever air pollution.

The unique system designed by ULIX Innovation, leading company in ecology, consists not only on treat the air, but also to recover the pentane which can be reused in a close system. The advantages are not only environmental, but also economical, since the pentane can be reused as raw material.

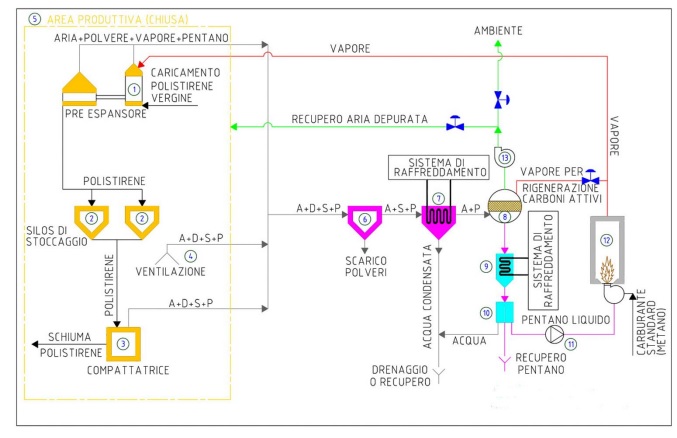

The plant designed by ULIX Innovation captures all the air stream polluted by pentane coming out of several stages of the process (pre-expansion, silos, block machine) via a interconnected vacuum system which can be adjusted automatically based on the air flow demand from the manufacturing process

Polluted air is contaminated with pentane, dust and water vapor [4]. After extracting dust with a special filter [6], and condensed the vapor with a cooling unit, the air is sent to one or the activated carbon beds where pentane is adsorbed [8]. Pentane is recovered through a water vapor stream and reduced into liquid phase via condensation [9]. Recovered pentane is stored in a tank ready to be used in the industrial process. In alternative the solvent is sent to the boiler [12], which produces steam for the polystyrene production machines. The boiler, designed by us, works with pentane, methane or a mixture of the two.

The air coming out from the activated carbon [13], purified from pentane and and dust, is sent to the production area again. In this way, a zero emission plant is employed, both in terms of pentane and emitted air.

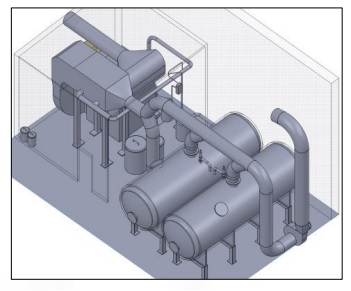

The plant is supplied turn-key, complete with electrical panel, electric system, PLC and operator interface terminal, assembled, calibrated and ready for production.

ADVANTAGES OF ULIX INNOVATION TECHNOLOGY :

- Very high efficiency of solvent removal (up to 99.8%)

- 100% GREEN system (Zero Emissions)

- Solvent Recovery with its reuse for heat production = economic saving + no environmental impact in the manufacturing process

- Government subsidies in many European and non-European countries

- Low energy consumption and less system management costs

- Modular plant design which allows further enlargements according to the flow to be treated

Technical features of “RECOVERY” section:

- Air flowrate to be treated 500 to 50.000 Nm3/h

- Type of solvent to be removed isopentane , normalpentane

- Electricity consumption ≈ 12KW (for each 10.000 Nm3/h of treated air)

- Industrial Water consumption ≈ 0.2 m3/h (for each 10.000 Nm3/h of treated air)

- Steam consumption Regenerated from pentane combustion

- Type of activated carbon Renewable in situ (lifetime > 18 years)

Services offered by ULIX INNOVATION :

- Study of the available spaces and realization of tailored layouts

- Study and optimization of existing suction lines

- Installation, start-up and in-situ calibration of the plant

- Customer service and spare parts maintenance

- Training sessions for staff for the proper use of the system

- Remote assistance and remote monitoring system

- Continuous monitoring of stack emissions