This unit is intended for industrial painting, polishing and lacquering industries, furniture factories, bathroom furniture, marble, cast marble and quartz processing industries. They guarantee, by means of volatile solvents (VOC) abatement, not only to comply with the emissions, but also to recover the solvents and resell them, turning into a low-cost investment. This unit is more convenient than a post-combustor since it has lower operating costs and much less methane consumption.

This process is applied on the painting lines, which, due to their characteristics, let volatile organic solvents (VOC) off in the atmosphere, causing air pollution. The unique feature of the ULIX Innovation plant is to purify the air from the VOC by a process of recover the solvents and send them to the boiler by a process with ZERO ENERGY CONSUMPTION. The advantages are:

- Environmental: solvents are recovered and burned to run the plant without methane, like regular postcombustors.

- Economical: there are many incentives in Europe for solvent recovery and the costs of the fuel is ZERO.

The ULIX Innovation plant sucks all the polluted air flows from the entire input points of the painting booth,

through a ramified fume hood system customized to all the applications.

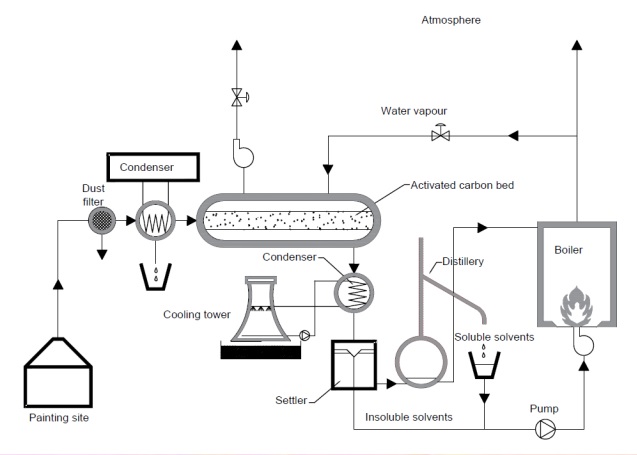

The contaminated air, after having removed the dust and water vapours via a condensing unit, is sent to one or more activated carbon beds, where solvents are adsorbed. Solvents are recovered by a water vapour stream which completely regenerates the carbon. The mixture of water and solvents is then condensed and insoluble solvents are separated from the water in liquid form. In the case of water-soluble solvents, they are separated by a distillation unit. The recovered solvents are stored in a dedicated tank and sent to the boiler. The steam generated from the boiler is used for the regeneration, as well as the output air, with a very high purity.

This system allows to have nearly ZERO emissions in the atmosphere.

The plant is supplied turn-key including the installation and calibration of the electric panel, control panel and dialog box. Dimensions range from 5 × 15 m for air flows of 20.000 m3/h and 5 × 25 m for air flows of 50.000 m3/h. We provide maintenance services in-situ to guarantee no interruption of productivity.

ADVANTAGES OF ULIX INNOVATION TECHNOLOGY:

– High efficiency of solvent removal (up to 95%)

– 100% green plant (ZERO EMISSIONS)

– Solvent recovery and utilization to produce heat = economic savings + no environmental impact

– Economical incentives in many EU and non-EU countries

– Low energy consumptions and low maintenance costs

– Plant modularity which allows further enlargements in relation to the flow rate

Technical features of the plant:

– Air flow to be treated from 5.000 to 150.000 m3/h

– Type of solvent do be removed any (polar and apolar)

– Methane consumptions Negligible (only for preheating of the boiler)

– Water consumptions ≈0.1 m3/h for every 10.000 Nm3/h of air to be treated

– Electricity consumption ≈150KW for every 10.000 Nm3/h of air to be treated (including the already installed fan)

– Carbon wear 15-20 years

– Product disposal costs None (only dust from filter)

Services offered by ULIX INNOVATION

– Design in 2D and 3D

– Space analysis and customized layout

– Investigation and optimization of the suction lines

– Construction, preassembling and testing in our working site

– Installation, start-up and calibration in-situ

– Maintenance and spare parts assistance

– Training sessions of personnel for the correct use of the plant

– Teleassistance and check-up from remote

– Continuous monitoring of stack emissions