Every year in Italy 800,000 tons of WEEE (waste electrical and electronic equipment) are produced. This equipment contains dangerous substances which, if dispersed, contaminate the environment and therefore require special disposal. The refrigerant gases used in refrigerators and air conditioners belong to this category: CFCs also known as freon. These compounds have a GreenHouse Potential (GWP) of 1430 and are the main culprits in the widening of the ozone hole.

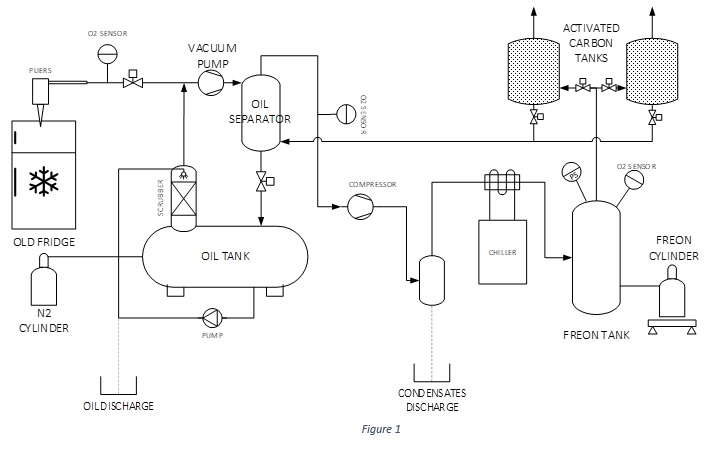

The ULIX Innovation system is capable of sucking freon and oil from exhausted refrigerators and recovering the gas with an efficiency very close to 100% and with a purity greater than 99% such that it can be reused for new appliances. The cycle works as follows: The operator, using pliers of our own creation, pierces the copper tube where the gas is contained; when the control system gives all the consents, the vacuum pump which absorbs oil and freon turns on. The Freon is separated from the oil in an oil separator: the oil is collected in a storage tank, while the Freon continues its journey. After being compressed by means of a compressor and cooled below its liquefaction point, it is stored in a tank, and then in a dedicated cylinder. The oil is further purified by stripping the gas dissolved in it and recovered. If there is air inside the circuit, a pressure switch will trigger the venting of the gas tank: the air will pass through an activated carbon filter and emitted into the atmosphere and the freon contained in it will in turn be recovered by the regeneration of activated carbon.

Due to its strong environmental impact, Freons have gradually been replaced by R600 and A2L refrigerants. In the case of these compounds, and in particular R600, the system will provide some additional safety measures due to the risk of flammability in order to make it compliant with the ATEX regulation. Therefore, a sensor will monitor the oxygen concentration in the 3 most critical points of the system and before the valve is opened on the manifold for gas suction from the caliper, further consents must be verified. If an oxygen concentration higher than the LOC (Limiting Oxygen Concentration) is detected in the system, a nitrogen purge will be activated by blowing away the oxygen present in the pipes. The system is completely automatic and managed by PLC even remotely and possibly interconnected with the factory IT systems compliant with the Industry 4.0 plan with which it is possible to obtain hyper-depreciation of 40%.

ADVANTAGES OF “ULIX INNOVATION” TECHNOLOGY:

- High recovery efficiency (< 1ppm) – ZERO disposal costs

- Low maintenance of the system

- Compact and easily movable system

SERVICES OFFERED BY “ULIX INNOVATION”:

- Study and optimization of the existing production process

- Staff training sections for complete use of the system

- Start-up and monitoring of the system at the customer’s site

- Remote teleassistance to check the correct functioning of the system